|

Sizing POB

Brake for Unwind Tension Control

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INPUT

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter Tension

|

|

pli

|

|

|

|

(see chart below if needed)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Roll Diameter:

|

|

in.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Web width

|

|

|

in.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Core diameter

|

|

in.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Web (Linear) Speed

|

|

ft/min

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CALCULATED RESULTS

|

|

Tension

Value Chart

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Foil .001 inches thick

|

|

1

|

|

|

|

|

|

|

Foil .002 inches thick

|

|

2

|

|

|

Tension

|

|

pli

|

|

Mylar .0005 inches thick

|

0.25

|

|

|

|

|

|

|

|

Mylar .001 inches thick

|

0.75

|

|

|

Maximum Torque

|

|

lb ft

|

|

|

Mylar .002 inches thick

|

1.5

|

|

|

|

|

|

|

|

|

|

Polyethylene .001 inches thick

|

0.25

|

|

|

Slip RPM (at full roll)

|

|

rpm

|

|

Polyethylene .002 inches

thick

|

0.5

|

|

|

|

|

|

|

Acetate .0005 inches

thick

|

0.25

|

|

|

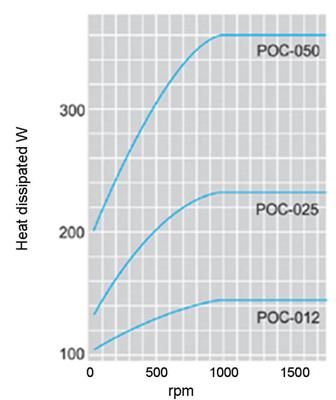

Heat Dissipated

|

|

W

|

|

Acetate .001 inches

thick

|

0.5

|

|

|

|

|

|

|

|

|

Acetate .002 inches

thick

|

1

|

|

|

Maximum RPM

|

|

rpm

|

|

Polystyrene .0005 inches thick

|

0.5

|

|

|

|

|

|

|

|

|

Polystyrene .001 inches thick

|

1

|

|

|

|

|

|

|

Polystyrene .002 inches

thick

|

2

|

|

|

|

Cellophane .001 inches

thick

|

0.5

|

|

|

|

Wax Paper .001 inches

thick

|

1

|

|

|

The

proper size brake must....

|

|

Wax Paper .002 inches thick

|

2

|

|

|

|

|

|

|

Newspaper .002 inches thick

|

0.25

|

|

|

have

sufficient torque

|

|

|

Newspaper .003 inches thick

|

0.75

|

|

|

be able to

dissipate the heat

|

|

|

Kraftpaper 0.005 inches

thick

|

1.5

|

|

|

not run

above rated speed

|

|

|

Kraftpaper 0.01 inches thick

|

4

|

|

|

|

|

|

Paperboard 8 pt.

|

|

3

|

|

|

|

|

|

|

Paperboard 12 pt.

|

|

4

|

|

|

The

following brakes meet your specifications:

|

|

Paperboard 15 pt.

|

|

5

|

|

|

|

|

|

|

|

Paperboard 20 pt.

|

|

7

|

|

|

|

|

|

|

|

Paperboard 25 pt.

|

|

9

|

|

|

|

|

|

|

Paperboard 30 pt.

|

|

1

|

|

|

|

|

|

|

Paper 15 lbs./ream

|

|

0.5

|

|

|

|

|

|

|

Paper 20 lbs./ream

|

|

0.75

|

|

|

|

|

|

Paper 30 lbs./ream

|

|

1

|

|

|

Choose

the smallest from above and verify on graphs below

|

|

Paper 40 lbs./ream

|

|

1.5

|

|

|

|

|

|

Paper 60 lbs./ream

|

|

2.5

|

|

|

|

|

|

Paper 100 lbs./ream

|

|

4

|

|

|

|

|

|

|

Sizing

Brake for Cycling or Controlled Starting or Stopping

|

|

|

|

|

|

|

|

|

|

|

INPUT

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter Tension

|

|

pli

|

|

|

|

(see chart above if needed)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Roll Diameter:

|

|

in.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Web width

|

|

|

in.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Core diameter

|

|

in.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Web (Linear) Speed

|

|

ft/min

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Roll Weight:

|

|

lbs.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Time to stop the

load

|

|

s

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CALCULATED RESULTS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tension

|

|

pli

|

|

|

|

|

|

|

|

|

|

|

|

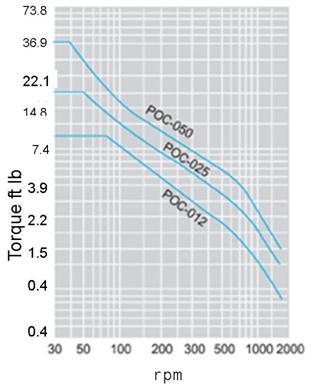

Torque (due to unwinding)

|

|

lb ft

|

|

|

|

|

|

|

|

|

|

Slip RPM (at full roll)

|

|

rpm

|

|

|

|

|

|

|

|

|

|

|

Heat Dissipated

|

|

W

|

|

|

|

|

|

|

|

|

|

|

Maximum RPM

|

|

rpm

|

|

|

|

|

|

|

|

|

|

|

Inertia

|

|

lbft^2

|

|

|

|

|

|

|

|

|

|

Torque (due to

inertia)

|

|

lb ft

|

|

|

(controlled

deceleration conditions)

|

|

|

|

|

|

|

|

|

|

|

|

Limiting torque

|

|

lb ft

|

|

|

|

|

|

|

|

|

|

|

|

The

proper size brake must....

|

|

|

|

|

|

|

have

sufficient torque

|

|

|

|

be

able to dissipate the heat

|

|

|

|

not

run above rated speed

|

|

|

|

|

|

|

The

following brakes meet your specifications:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Choose

the smallest from above and verify on graph below

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|